Production planning, purchasing, stores and logistics

Tenon Engineering is able to deliver complex products on time to its customers because the necessary components and resources are always available and are in synchronisation with the production schedule.

We achieve this by rigorous systems and control of the supply chain. By using concepts like MTA (make to availability) and PTA (purchase to availability) we can ensure availability of components, whilst managing the investment in working capital.

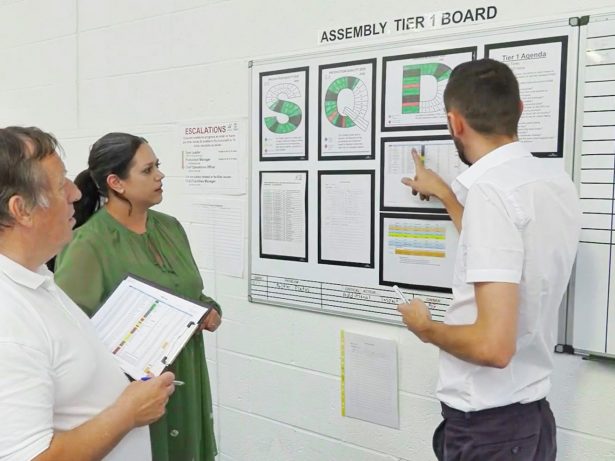

Tenon Engineering’s Flow Department incorporates production planning, purchasing, stores and logistics. It is their job to manage the flow of our supplies and products through our whole production and delivery cycle. Quality management and production engineering are critical to the reliability of this system.